Integrated solutions

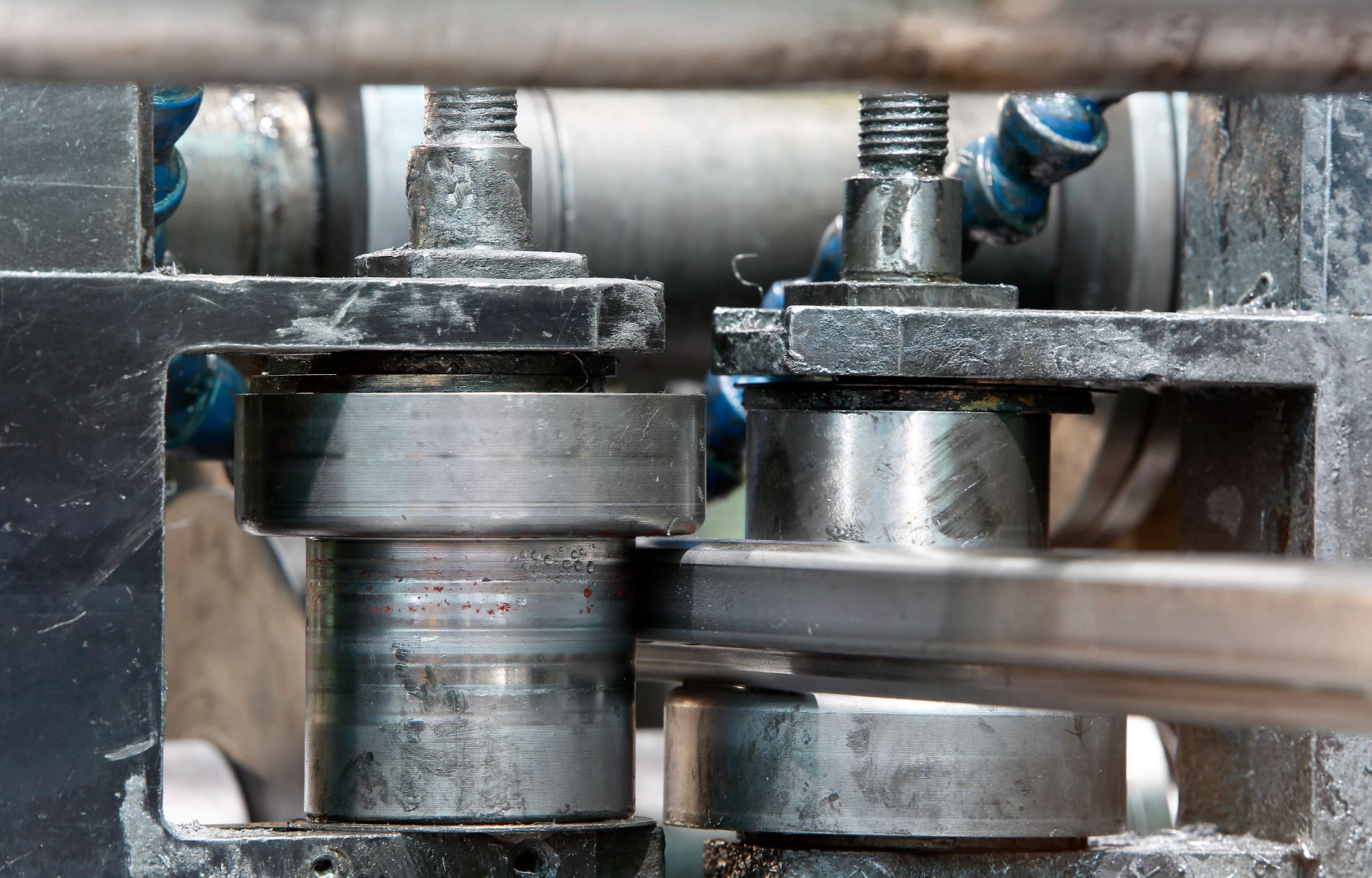

Perfil en Frío possesses extremely versatile machinery in order to meet its customers’ different requirements. We cover a wide range of sectors in which our steel profiles can be put to use, meaning that we need very different tools for each.

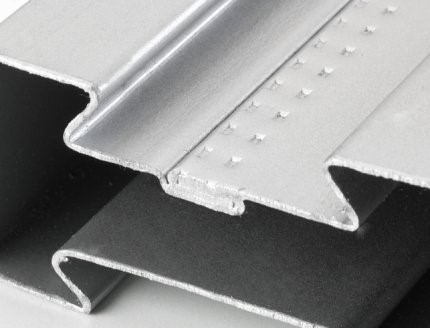

We specialize in profiles with made-to-measure shapes, either open or welded, and offer the possibility of integrating different machining operations and finishes, making functions and applications beyond the reach of commercial tubes and profiles possible.

At present, our production capacities are as follows:

- Thickness: from 0.4 mm to 6 mm.

- Maximum width: 700 mm, with the possibility of up to 1,300 mm in certain cases.

- Maximum length: 20,000 mm.

Production line solutions

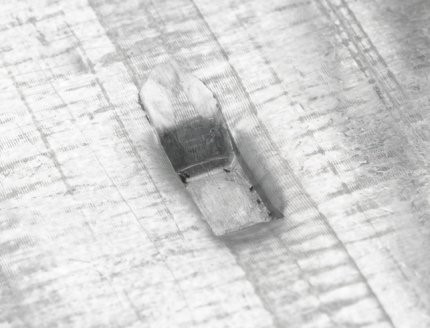

Operations integrated on the profile production line make it possible to add functionality to the product, whilst also cutting the costs that second external processes would involve.

OPERATIONS INTEGRATED ON THE PRODUCTION LINE:

- Special shapes

- Perforations and drawing

- Cut to size

- Welding

- Clinching, stitching and crimping systems.

- Specific solutions (ink printing, end flattening, and much more)